Ismail Industries’ technologically advanced rPET plant is a purpose-built, 100% bottle-to-bottle recycling facility designed to advance circular sustainability through cutting-edge machinery and responsible operations.

At the core of the plant are world-leading recycling and polymerization systems, including:

- Starlinger (Austria) PET extrusion and polymerization lines for consistent, food-grade rPET production.

- BoReTech (China) high-performance washing line ensuring superior cleaning efficiency.

- Sesotec AI-driven sorting technology delivering exceptional purity levels required for food-contact applications.

- Allied utilities sourced from globally recognized suppliers to ensure world-class reliability and performance.

Supporting these systems is a robust green infrastructure featuring biomass-based heaters, waste-energy-recovery chillers, a closed-loop EPA-compliant water system, solar power generation, and energy-efficient compressors—further reducing the overall environmental footprint.

Through this investment, Ismail Industries reinforces its commitment to producing fully recycled, food-grade rPET and strengthening the circular economy by offering sustainable, high-quality packaging materials for global and domestic brands.

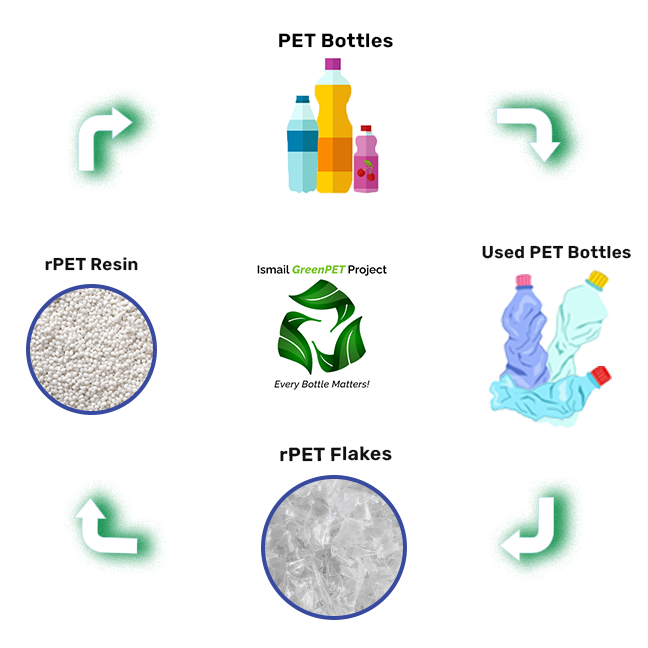

rPET VALUE CHAIN

Technical Data Sheets

Get in Touch

For Sales Inquiries:

Email: info@ismailresin.com.pk

.png)